Project Background

A renowned beer brand, in response to production capacity upgrades, strategically chose Foshan in the Lingnan Water Town region to build a new intelligent manufacturing base. Leveraging the superior water resources of the Xijiang River Basin, the project is centered on “ecological priority and digital empowerment.” It aims to create a green benchmark factory that integrates clean production, energy recycling, and intelligent connectivity—setting a new standard for sustainable development in the Greater Bay Area's beverage industry.

Requirements:

-

Smart Infrastructure

High-speed communication network supporting Industrial IoT (IIoT), 5G/Wi-Fi 6, and fiber-optic connectivity for real-time data transmission, device interconnectivity, and low-latency control.

Features: Network redundancy, high bandwidth, wide coverage, and anti-interference capabilities. -

Energy Management & Environmental Monitoring

Smart Energy Management System that integrates smart meters, sensors, and SCADA for real-time monitoring of water, electricity, and gas usage.

Goals: Optimize energy allocation, reduce energy consumption per unit, and achieve carbon neutrality.

Also monitors temperature, humidity, air quality, noise, and harmful gases, with HVAC system integration to enhance comfort and comply with environmental regulations. -

Security & Emergency Management

Smart security systems including facial recognition access control, AI-powered video surveillance, electronic patrols, and perimeter intrusion detection.

Combines HD cameras, edge AI computing, and integration with fire alarm/access/alarm systems to prevent safety risks and protect production data and assets. -

Data Integration & Intelligent Decision-Making

A unified data platform that integrates MES, ERP, energy, and security systems to eliminate information silos.

Powered by industrial big data, digital twins, and cloud computing for data-driven production optimization and resource scheduling.

Solution Summary

-

Structured Cabling: CAT7 cabling supports 10G transmission and up to 40G

throughput, ensuring high-speed connectivity across production and office zones.

Full Wi-Fi AP coverage for wireless access.

-

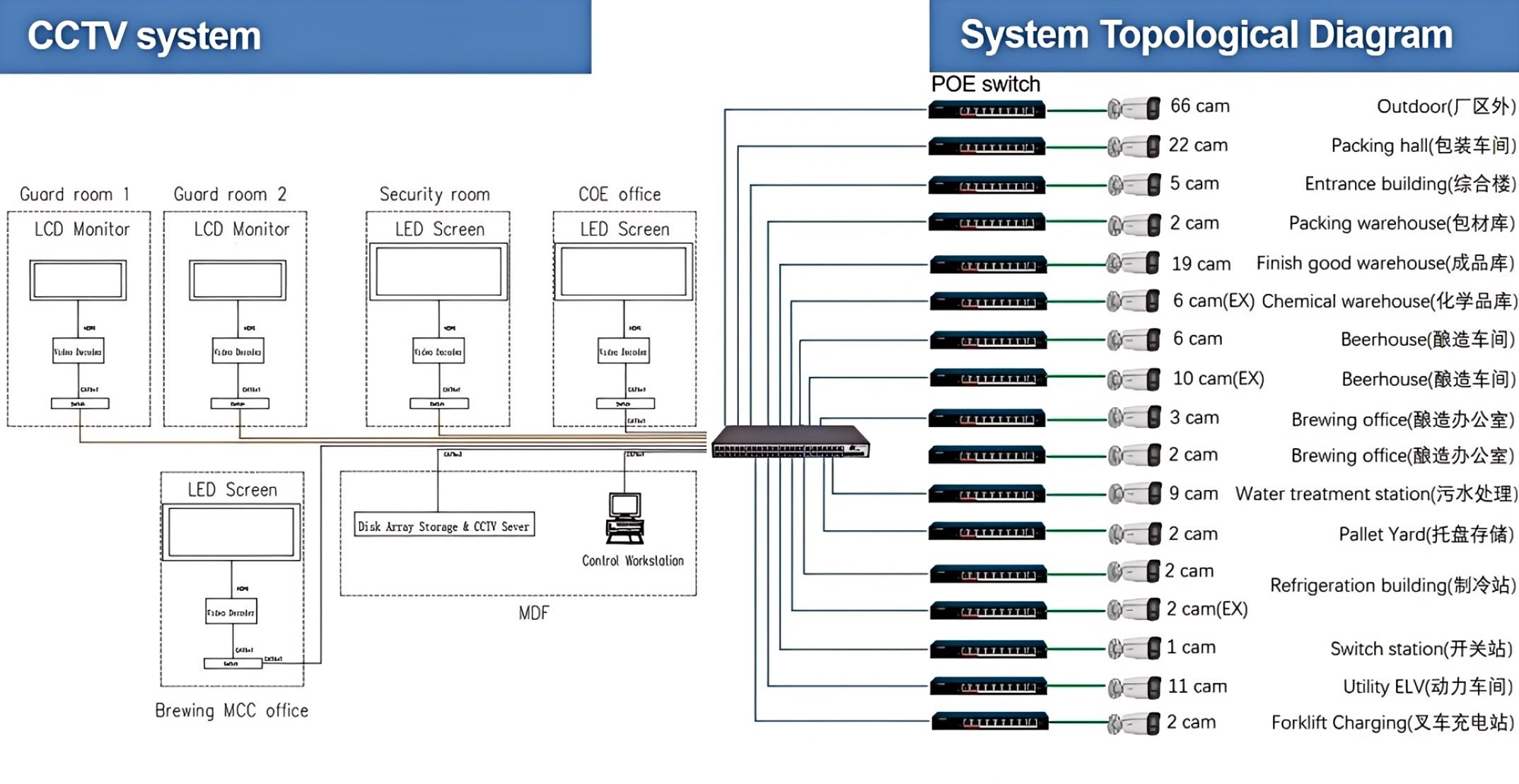

Video Surveillance: AI-powered HD cameras provide full-site coverage. Behavior

analytics enhance security management based on visual feedback and intelligent

alerts.

-

IT Equipment Rooms: Two modular data centers (primary and backup) for neat,

efficient management and future scalability.

-

Meeting System: Scene-based customization with solutions such as cafeteria LED

video walls, large meeting displays, Logitech conferencing, and QSC professional

AV integration.

Advantages

- One-Stop Design & Delivery: Reduces cross-vendor coordination issues.

- Highly Integrated Intelligent Design: Enables multi-system synergy and centralized management.

- High Degree of Automation: Enhanced customer experience and operational efficiency.

Customer Pain Points & Challenges

- Large site with limited management personnel—high demand for automation.

- Numerous new systems in a greenfield factory—high integration complexity.

- Difficult cross-departmental coordination.

Customer Benefits

-

Smart Operations Management:

Asia's largest R&D center equipped with high-speed, stable networks; office zones support HD video conferencing across locations. First-of-its-kind air-conditioned brewery, MES-driven automated production lines, and intelligent wired/wireless networks with smart surveillance and access systems improve production safety. -

High-Reliability Network Architecture:

Dual core data centers with dual fiber links provide redundant backup and ensure operational continuity even during single-link failure. -

Refined Personnel Management:

Smart access control restricts staff movement by shift and permissions; visitor access is temporary and route-controlled. Vehicles are classified for different access levels between employees and guests.