Core Value

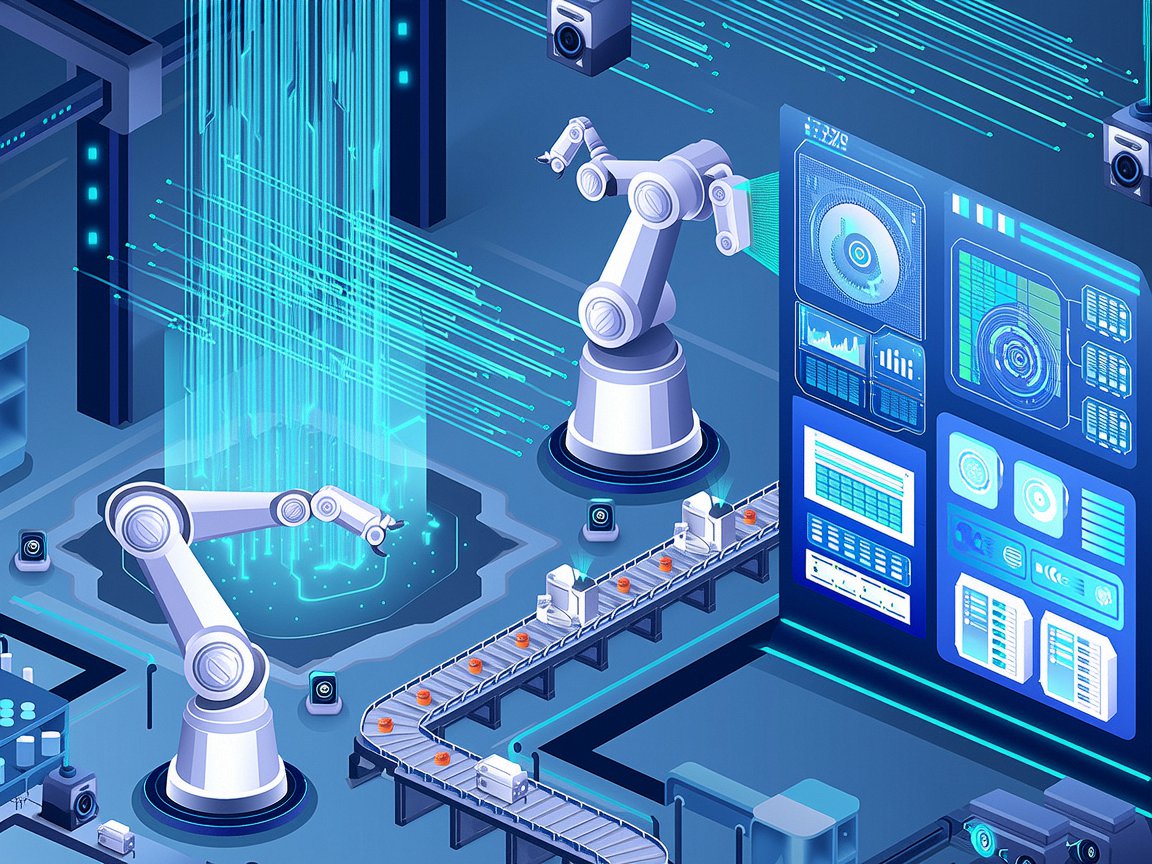

The industrial internet converged network focuses on the digital transformation needs of traditional manufacturing. By deeply integrating Information Technology (IT) and Operational Technology (OT), it builds a secure, agile, and intelligent foundation for production networks. Its core value lies in breaking down data silos, enhancing security, and driving production optimization—empowering enterprises to achieve transparent production, refined management, and intelligent decision-making, and supporting the implementation of the new industrialization strategy.

Technical Features

- Optimized Network Architecture: A layered and redundant network design ensures high availability. The layered architecture separates network zones based on function and security level for easier management and maintenance, while redundancy ensures business continuity even if some devices fail, minimizing the impact of single points of failure.

- Enhanced Security Protection: Multiple security devices and technologies such as firewalls, Intrusion Detection Systems (IDS), and Intrusion Prevention Systems (IPS) are deployed to mitigate network threats. Firewalls filter traffic based on rules; IDS monitors suspicious activities in real time and generates alerts; IPS actively blocks threats, offering comprehensive protection.

- Data Collection and Analysis: Real-time collection and deep analysis of IT and OT data provide strong support for business decision-making. Data acquisition devices gather key data from various sources, and analytics tools—leveraging big data and AI—uncover hidden insights, helping companies optimize production, improve efficiency, and implement predictive maintenance.

Application Scenarios

- Smart Manufacturing: In smart factories, IT/OT convergence enables real-time connectivity between production equipment and management systems. Sensors and smart meters collect production data (e.g., temperature, pressure, speed) and send it to the management system, which analyzes processes to identify bottlenecks and optimization opportunities. For example, in an automotive assembly line, data is used to adjust robotic arm speed and trajectory to enhance welding and assembly accuracy, improving efficiency and product quality.

- Smart Logistics: IT/OT convergence enables interconnection of warehouse equipment like automated shelves and AGVs. The Warehouse Management System (WMS) integrates with these devices to track item location and inventory levels in real time. For example, in an e-commerce warehouse, when an order is generated, the WMS calculates the optimal picking route based on item locations and directs AGVs and staff to perform the operation—improving picking efficiency.

Business Advantages

- Increased Production Efficiency: Minimizes downtime and improves equipment utilization.

- Cost Reduction: Reduces financial losses associated with security incidents.

- Enhanced Competitiveness: Enables rapid market response and business model innovation.